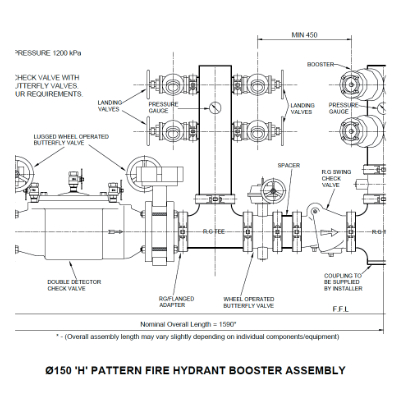

This may be as simple as an attack hydrant requirement such as a dual hydrant riser or a more complicated fire brigade quad booster point complete with feed hydrants isolating and check valves.

Fire hydrant booster assembly dimensions.

Booster assemblies are manufactured to conform to the requirement of as2419 to relevant local authorities.

Fire boosters cabinets 24.

Booster and hydrant assemblies consist of arrangements of valves pipe work to suit specific site fire protection needs.

Cabinet for 100 150 hydrant booster storz suction riser painted 2 0mx0 6m deep product code.

Dimensions installation details installation layout cabinet product code.

Fire boosters cabinets.

The nominal diameter for a hydrant valve connection is 65mm.

All components comply to the requirements of as2419.

Any fabricated components are hot dipped galvanised as required in as2419.

1600mm x 650mm fix cabinet through feet to concrete plinth.

Numerous dry and wet barrel designs are available that meet stringent ul fm requirements some with maximum working pressures of 350psi full line catalog.

1400mm cabinet assembly for 100mm dual booster feed hydrant assembly b i c.

100 off 4 239 incl gst.

As a critical piece of any emergency response system used to preserve lives and property all mueller fire hydrants are designed built and tested to assure high performance long life and dependability.

The end point of a fire hydrant system is the hydrant also known as a hydrant valve or landing valve strategically located throughout a building in accordance with the provisions of as2419.